WP1 IBA fine fraction characterization

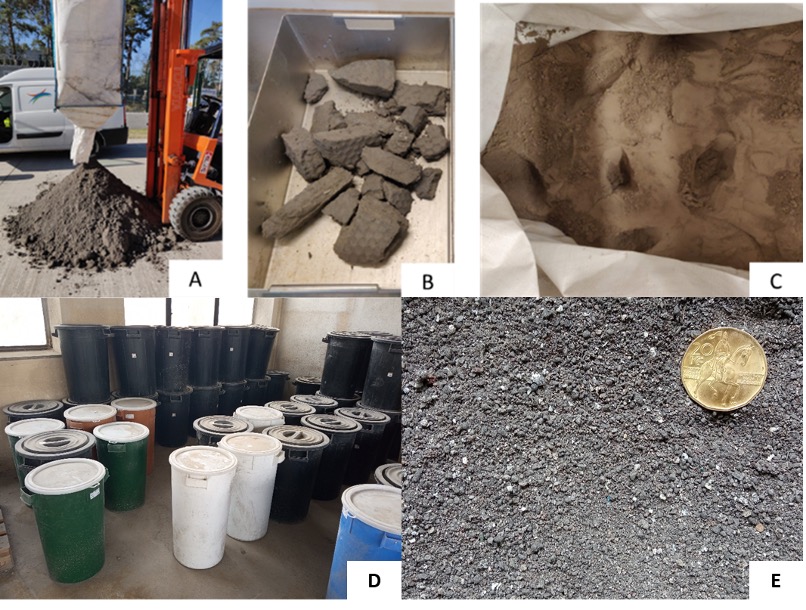

The main objective of this work package is to analyze the physicochemical composition of IBA fine products generated by the incineration plants of ZEVO (Prague, Czech Republic) and INDAVER (Antwerp, Belgium) used within the ReFina project. For this purpose, a total of four different samples were analyzed: The samples from INDAVER consist of the ultra-fine product, up to 63 microns, called filter cake and the sand IBA (0.063-2 millimeters) from its material recovery plant, and a mixture of fly and boiler ashes coming from the fluidized bed incinerator (Be-Fly/Boiler). The IBA sample from ZEVO consists of the fine fraction, up to 2 millimeters, directly collected from the facility’s stockpile (Figure 1).

For this purpose, the Flemish Institute for Technological Research (VITO) carried out the sampling and analysis of INDAVER’s samples, while the Institute of Chemical Process Fundamentals (ICPF) performed the sampling campaign and analysis of the samples from ZEVO. Additionally, in order to improve the quality of the analytical work, cross-analyses were carried out between the research institutes.

The following physical and chemical analyses were carried out for this characterization: Particle size distribution by a laser measuring device and sieve tower method. Morphological and mineralogical characterization by employing X-ray powder diffraction (XRD) and scanning electron microscope (SEM) together with energy-dispersive X-ray (EDX) methods. The chemical characterization through energy dispersive X-ray fluorescence spectrometer (ED-XRF), Handheld X-ray fluorescence (XRF), and inductively coupled plasma atomic emission spectroscopy (ICP-OES) after acid digestion. In parallel, both institutes carried out an analysis to determine the environmental quality of the samples according to the requirements of each region, and the determination of elemental aluminum which is an essential parameter for work-package 4. Finally, a quantitative method to determine the amount of metallic elements in the fine fraction of the IBA has developed.

The results obtained by these analytical methods are consistent with the values reported in technical literature. The table below shows relevant concentrations of valuable non-ferrous metals such as copper, zinc, or aluminum in the analyzed samples. In summary, higher concentration of metals like copper and zinc was found in the INDAVER´s samples, while the concentration of aluminum and elemental aluminum is higher in the ZEVO’s bottom ash. In addition, the characterization of the environmental parameters (according to the legislation in force) showed that the INDAVER samples had an excess of element leaching as copper. Moreover, the morphological analyses showed that in case of the coarse samples the metallic grains are massive, while in the fine samples the metallic grains are dispersed throughout the matrix (Figure 2).

Finally, the method developed to determine the amount of metallic elements in the IBA fine fraction showed that approximately 65% wt. of copper and 4% wt. of zinc reported by the chemical analysis can be considered metallic.

Table 1. Summary of the most valuable metals from the ReFina samples

| [g/kg.] | Czech bottom ash | Belgium- Sand bottom ash | Belgium – Filter Cake | Belgium – Fly/Boiler ash |

| Copper | 1,6 | 3,7 | 1,7 | 1,9 |

| Zinc | 3,6 | 6,1 | 4,4 | 2,7 |

| Aluminum | 65,7 | 44,5 | 36,3 | 33,1 |

| Elemental aluminum | 10,0 | 8,5 | n.a. | n.a. |

| n.a. non analyzed element | ||||

Figure 1. ReFina samples collected by VITO from INDAVER: Sand Bottom Ash (A); Filter Cake (B); Fly/Boiler (C). ReFina samples collected by ICPF from ZEVO: Fine Bottom Ash stockpile (D);Fine Bottom Ash sample (E).

Figure 2. Distribution of copper in INDAVER samples by SEM-EDX analysis: Sand Bottom Ash (A), Filter Cake (B), Fly/Boiler (C).